Together with our partner Bioenergia Terenov we have installed a 1 MW pellet burner in front of the steam boiler in Portugal. The system helps the customer to disinfect wood bark for mulch production three times cheaper than before, saving each day over a lot of money. To ensure constant work of the factory, the burner must be at continuous work.

The biggest difference of running a pellet burner with steam boiler instead of hot water boiler, is that it has to run according to the pressure in the boiler and not by temperature. Power levels change according to a prediction created by analyzing the pressure data, determining the pressure change and the rate of the change.

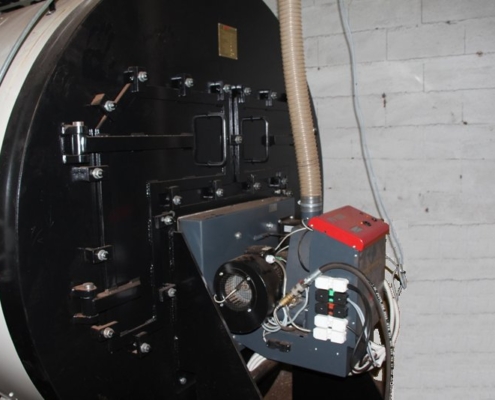

Constant steam pressure is vital to run the production without stops. The boiler with PV1000a burner is capable to produce 1500 kg of steam per hour. Most of the time the output of the system is about 700-800kg of steam per hour with the pressure 6 bar.

Installation year: 2014